Hydraulic Seals

Although hydraulic seals are only accessories, they play a very important role in the structural equipment of the entire system. Information about hydraulic seals will help you easily choose and purchase accurately and quickly.

1. What is hydraulic seal?

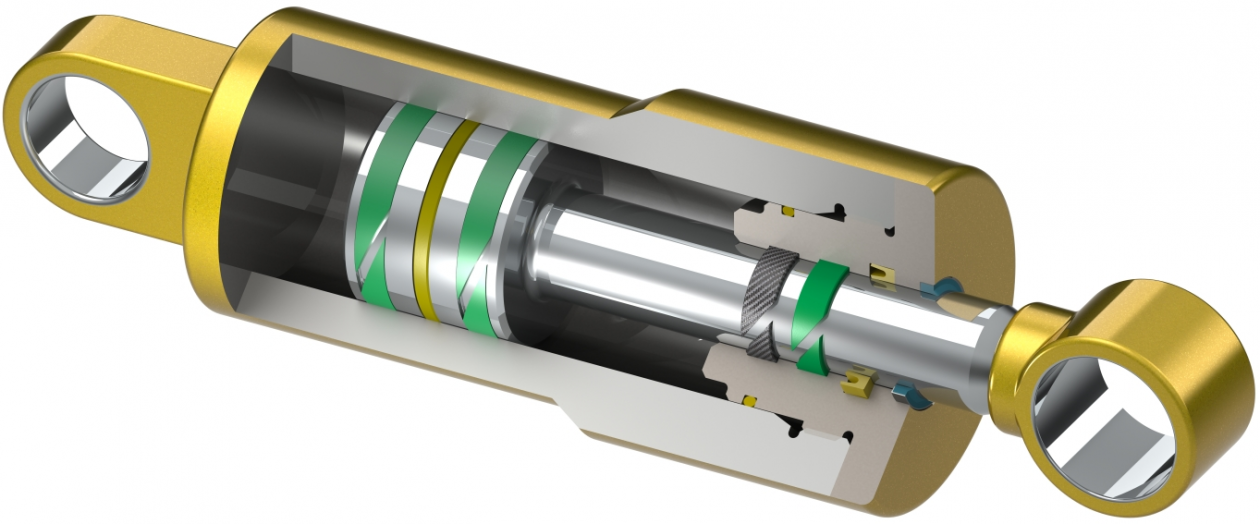

Seal gaskets are small parts installed at joints or grooves on parts, specifically hydraulic cylinders and pneumatic cylinders. The function of these pneumatic cylinder seals and hydraulic cylinder seals is to seal the gaps between joints at a number of locations where different parts are installed.

In the structure of a conventional pneumatic cylinder, it will be divided into two parts: low pressure and high pressure chambers, completely separate from each other. Because there is a pressure difference between the two chambers, it causes the piston to move forward. But if this difference does not have a seal, it will leak oil and lose pressure, causing the cylinder to not operate as originally designed.

Therefore, the seal base will be responsible for sealing the gap between these two pressure chambers. It will be installed at any position in the pneumatic or oil cylinder with a sealing function.

2. Where are hydraulic seals installed? How to install hydraulic seals

Hydraulic seals are specialized parts, installed at gaps in hydraulic cylinders. In the cylinder, there are many types of seals installed in different positions, so the way to install the hydraulic seal and the way to replace the hydraulic seal are also different.

- Static cylinder seal

Its function is to seal the seal in place. The working conditions of this type of seal are the most stable compared to other seals in the cylinder.

- Rubber seal in hydraulic cylinder

It is also known by the English name Seal, depending on whether it is installed on a pneumatic cylinder or an oil cylinder, its name is called air seal and oil seal. This seal will be subjected to uneven pressure during operation and has the effect of sealing against leaks

- Hydraulic cylinder guide

You should be able to distinguish the seal from the guide ring. For large-sized hydraulic cylinders, they always bear large loads during the working process. The piston will always move along the cylinder to change pressure.

However, in some machines, the piston will move in a slightly unusual direction, then the rod and cylinder tube will no longer be parallel to each other, causing the piston to lean against the tube more, so a guide ring is needed to Prevents cylinder wear.

3. Instructions for choosing hydraulic seals

If you need to find air cylinder seals for pneumatic cylinders or hydraulic seals for oil cylinders, please carefully read the information below.

3.1 Working temperature

Working temperature is the first factor to consider. Normal gaskets will withstand temperatures from -30 degrees Celsius to 100 degrees Celsius. For specific jobs, the working temperature will be higher than normal, so choose seals that can withstand heat better than the system temperature. system.

Those are gaskets made from material silicone, simrit, fluorocacbon or metal gaskets that we often call piston rings.

3.2 Working pressure

Next is the pressure factor of the seals. Accurate determination of pressure will help select the appropriate type of high pressure hydraulic seal. There are two types of pressure that need to be distinguished: breakdown pressure and working pressure.

The destructive pressure will be much greater than the working pressure of the seal.

When working, the seals will be subjected to high pressure (high pressure hydraulic seals) and increased temperature, then their task is to seal the gaps. However, the increased pressure will reach a level that can damage and destroy the high-pressure hydraulic seal, which will greatly affect the surrounding parts. Therefore, the system needs to be installed with a one-way valve and a safety valve to ensure safe operation.

Consider choosing a gasket that can withstand high pressure. Currently, with modern technology, there are gaskets that, in addition to sealing, can also release oil when subjected to high pressure to help protect the system safely.

3.3 Determine structure and size

After temperature and pressure, the next factor to consider is the size of the seal. Different sealing locations will require different sizes. There are different types of seals for customers to choose from: Iron core seals, regular rubber seals, smart seals.

It is necessary to accurately determine the parameters: inner diameter, outer diameter, thickness of the seal gasket so that during installation there is no oil or fuel leakage.

3.4 Determine the operating medium

Nowadays, the working medium of cylinders is usually hydraulic oil. As for cylinders in factories and chemical plants, the medium may be the chemicals in the cylinder.

Therefore, it is necessary to choose the correct type of seal gasket to use to avoid the destruction of the medium on the seal gasket.

4. Selling hydraulic seals, addresses selling hydraulic seals in Hanoi

Where to buy hydraulic seals? Which reputable address provides hydraulic seals in Hanoi, which hydraulic seals to sell is a very difficult problem for customers looking to buy seals.

With many years of experience in the profession and always trusted by customers and using Device4u products. With a technical team who is knowledgeable about technical specifications and types of seals and can guide customers on how to install hydraulic seals and how to replace hydraulic seals. We are Device4u Trading and Services Co., Ltd. committed to providing hydraulic seals, NOK hydraulic seals, high pressure hydraulic seals ensuring quality, durability, warranty and flexible return when customers use them. our products.

Hydraulic seal prices are guaranteed to be the cheapest in the market in Hanoi as well as domestically. All NOK hydraulic seals and seals are 100% new and unused and most are in stock and we deliver nationwide so ordering is extremely easy and fast.

If you want to buy NOK hydraulic seals, Hanoi hydraulic seals or have any questions or need any advice about seal sets, please contact us for a quote on NOK hydraulic seals and answers. and 24/7 support via hotline:

DEVICE4U TRADING AND SERVICES COMPANY LIMITED

Address: Yen Vinh, Kim Chung Commune, Hoai Duc District, City. Hanoi

Phone: 0986.347.568 – 0974.16.13.18

Email: device4u.ct@gmail.com